Automatic Power Factor Improvement Device

In an era where energy efficiency and cost-effectiveness are paramount, our “Automatic Power Factor Improver” stands as a cutting-edge solution designed to optimize the performance of electrical systems. This device not only enhances power utilization but also significantly reduces operational costs by maintaining an optimal power factor across various load conditions.

What is power factor?

Power factor is a critical parameter that measures the efficiency of electrical power usage in a system. It is defined as the ratio of real power (used to perform work) to apparent power (total power supplied to the circuit). A low power factor indicates the presence of a high amount of reactive power, which does not contribute to work but adds to the total power consumption, leading to inefficiencies. A poor power factor can result from inductive loads, such as motors and transformers, which are common in industrial and commercial settings. This not only leads to increased energy bills but also imposes additional strain on the electrical infrastructure.

How the Automatic Power Factor Improver Works?

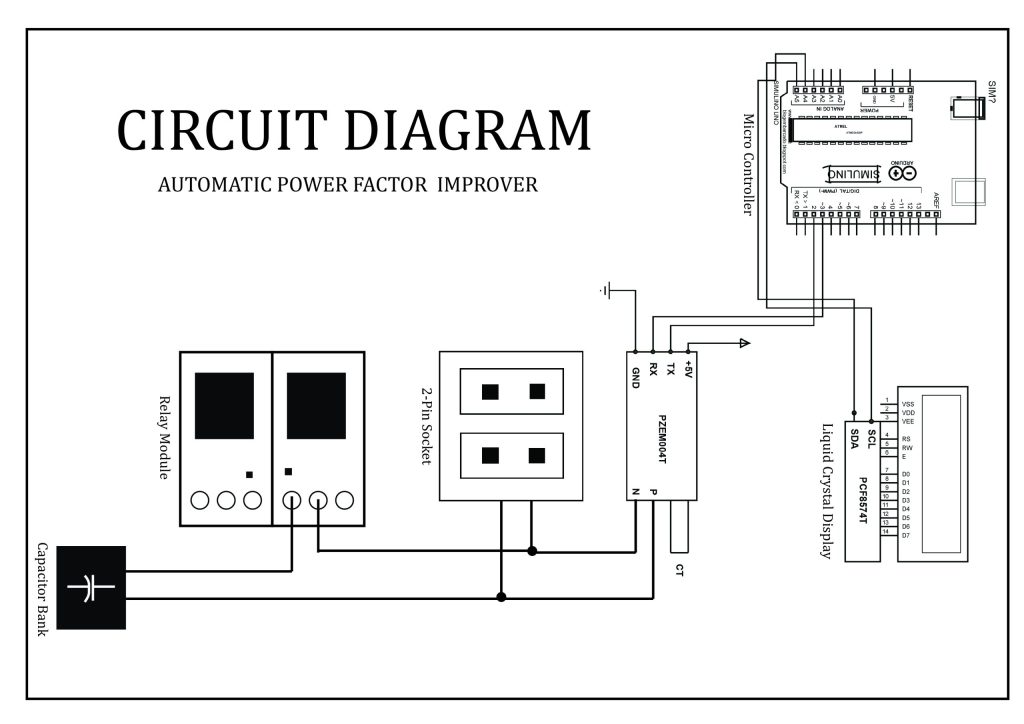

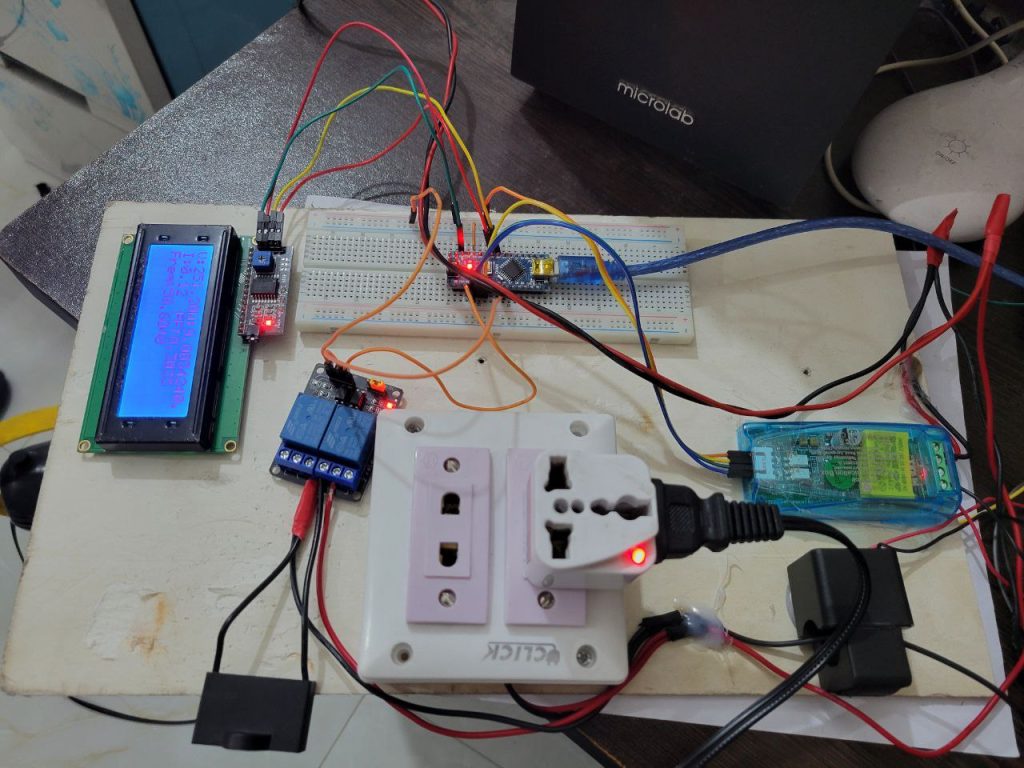

The Automatic Power Factor Improver is engineered to continuously monitor the power factor in real-time. When the system detects a drop in power factor below a predefined threshold, it automatically engages reactive power compensation elements, specifically capacitors, to correct the imbalance. This dynamic adjustment process involves several key components:

– Real-Time Monitoring: The device uses a combination of sensors and a PZEM004T AC Communication Box to measure essential electrical parameters, including voltage, current, power, and energy consumption. This data is processed by the Arduino Nano microcontroller, which acts as the control center of the system.

– Reactive Power Compensation: Upon detecting a suboptimal power factor (typically below 0.9), the Arduino triggers a relay module that connects a capacitor bank to the system. The capacitors inject reactive power into the circuit, offsetting the inductive load and improving the power factor towards unity.

– Automatic Disconnection: Once the power factor is corrected and returns above the threshold, the relay disconnects the capacitor bank, ensuring that the system only operates when necessary. This selective engagement minimizes wear on the components and prevents overcorrection, which could lead to a leading power factor (excess capacitive power), potentially causing instability in the system.

Key Components and Their Roles

The success of the Automatic Power Factor Improver relies on the precise interaction of various components:

– Arduino Nano Microcontroller: A compact yet powerful controller that processes real-time data and manages the activation of the capacitor bank through the relay module. Its small size and versatility make it ideal for integration into various electrical systems.

– 16×4 LCD Display: This display module provides a user-friendly interface, showing real-time readings of voltage, current, power, frequency, and power factor. Users can easily monitor the system’s performance and make informed decisions if manual intervention is required.

– PZEM004T AC Communication Box: A multifunctional device capable of measuring key electrical parameters with high accuracy. It plays a crucial role in providing the data needed for real-time monitoring and decision-making by the Arduino Nano.

– PZCT-02 Current Transformer: Used to measure the alternating current in the system, this transformer ensures that the current data fed into the system is accurate, enabling precise control of the power factor correction process.

– Relay Module: This electronic switch interfaces the low-voltage control signals from the Arduino with the higher voltage required to connect or disconnect the capacitor bank. Its role is vital in ensuring the capacitors are engaged only when necessary.

– Capacitor Bank (1.5 microfarad): The heart of the power factor correction process, these capacitors provide the necessary reactive power compensation to improve the power factor.

Advantages of the Automatic Power Factor Improver

Implementing this advanced power factor correction system offers numerous benefits:

– Significant Energy Cost Savings: By minimizing reactive power in the system, the device reduces the total power consumption, leading to lower electricity bills.

– Enhanced System Efficiency: With a corrected power factor, electrical systems experience fewer losses, leading to improved overall efficiency and reduced strain on the power distribution infrastructure.

– Increased Load Handling Capacity: By improving the power factor, the system effectively releases additional capacity, allowing the existing electrical infrastructure to handle more real power without needing expensive upgrades.

– Reduction in Voltage Drops: Optimizing the power factor reduces the voltage drop across power lines, ensuring stable voltage levels throughout the system, which is crucial for the reliable operation of sensitive equipment.

– Compliance with Regulatory Standards: Many industries and commercial operations are required by regulatory bodies to maintain a certain power factor. This device helps businesses comply with these regulations, avoiding potential fines and penalties.

– Prolonged Equipment Lifespan: With reduced reactive power, the stress on electrical components is minimized, leading to a longer lifespan and reduced maintenance costs for transformers, generators, and other critical equipment.

– Improved Power Quality and System Stability: The device contributes to a more stable and reliable power system by reducing fluctuations in voltage and current, which is particularly important in industries where precision and reliability are paramount.

Real-World Applications

The Automatic Power Factor Improver is versatile and applicable across various sectors, including:

– Industrial Facilities: Ideal for factories and manufacturing plants where large, inductive loads are common. It helps reduce energy costs and avoid penalties for poor power factor.

– Commercial Buildings: Office buildings, malls, and hotels can benefit from improved energy efficiency and lower operational costs.

– Data Centers: Ensures the stable and efficient operation of critical IT infrastructure by maintaining a high power factor.

– Healthcare Facilities: Hospitals with diverse and sensitive electrical loads benefit from stable and efficient power delivery.

– Renewable Energy Integration: Assists in the seamless integration of renewable energy sources like solar and wind into the power grid by ensuring grid stability and efficient energy transfer.

Our “Automatic Power Factor Improver” represents a sophisticated, yet accessible solution to one of the most common challenges in electrical systems—poor power factor. By leveraging advanced microcontroller technology, real-time monitoring, and dynamic reactive power compensation, this device offers substantial long-term benefits, including reduced energy costs, enhanced system efficiency, and extended equipment lifespan. Its adaptability across various industries underscores its importance in the modern drive towards sustainable and efficient electrical systems. This project is not just a technical achievement but a practical step towards more environmentally conscious and cost-effective energy use.